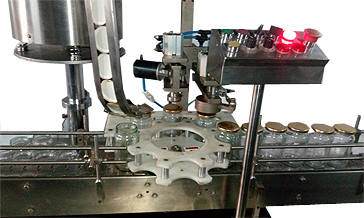

Lug Capping Machine

A Lug Capping Machine is a piece of industrial equipment designed to securely cap jars or bottles using lug caps. These caps are commonly used in food, beverage, and pharmaceutical industries for sealing glass containers to maintain product integrity and freshness. Lug caps have small protruding lugs (or threads) inside the cap that align with the threads on the jar's neck, providing a tight seal when properly applied.

Key Features of Lug Capping Machine :

- A Lug Capping Machine is commonly used in industries like food and beverage, pharmaceuticals, and cosmetics for sealing jars or containers with lug caps.

- Versatile Cap Compatibility is suitable for sealing a variety of container sizes and shapes with lug caps and adjustable to handle different cap sizes. High-Speed Operation is designed to handle large-scale production with efficient and fast capping capabilities. Consistent Torque Control ensures uniform sealing torque, minimizing the risk of under-tightening or over-tightening.

- Automation options are available in fully automatic, semi-automatic, or manual models, depending on production requirements. Automatic machines are equipped with conveyors and cap feeders for seamless operation. They are made from durable materials, typically stainless steel, to resist corrosion and wear and designed for long-term industrial use.

- These machines have adjustable settings for container and cap sizes, easy to clean and maintain, adhering to hygiene standards. Many lug capping machines feature vacuum sealing for improved product shelf life, especially for food products like jams, sauces, and pickles.

- Lug Capping Machines have intuitive control panels, often with touchscreens for easy operation and monitoring. It also includes features like speed adjustment, fault detection, and production statistics. The machines are equipped with safety guards and interlock systems to prevent accidents during operation. They are energy efficient designed to consume minimal power while maintaining high efficiency.

Types of Lug Capping Machines :

Lug capping machines are used to apply lug caps (commonly seen on jars and bottles with screw threads, like those for sauces, jams, or pickles) securely onto containers. These machines are used in industries such as food, beverages, and pharmaceuticals.

- Manual Lug Capping Machines : They are operated by hand, suitable for small-scale production, Cost-effective and simple to use and ideal for small businesses or low-volume operations.

- Semi-Automatic Lug Capping Machines : They are partially automated but requires manual placement or removal of containers, suitable for medium-scale production. Balances cost and productivity, making it popular for growing businesses.

- Fully Automatic Lug Capping Machines : These are Fully automated, including cap placement, tightening, and container movement. Have High speed and consistency, perfect for large-scale production. They are often integrated with other packaging equipment for streamlined operations.

- Single-Head Lug Capping Machines : These machines are equipped with one capping head, suitable for low to medium production speeds and are often used in semi-automatic or compact automated setups.

- Multi-Head Lug Capping Machines : They are equipped with multiple capping heads, allowing simultaneous capping of multiple containers, ideal for high-speed production lines and are used in industries with high-volume demands.

- Rotary Lug Capping Machines : The Containers are fed into a rotating system for high-speed capping. These machines are commonly used in large production setups for continuous operations and are highly efficient for industries requiring rapid production cycles.

- Inline Lug Capping Machines : The containers move in a straight line through the machine for capping. They are suitable for moderate production speeds and are easier to set up and integrate into existing lines.

- Vacuum Lug Capping Machines : These machines creates a vacuum seal while capping to preserve product freshness. They are often used in the food industry for items like jams, sauces, and pickles and ensures better shelf life by removing air from the container.

- Pneumatic Lug Capping Machines : They operate using compressed air to tighten the lug caps, provides consistent torque for a secure seal and are suitable for environments where electricity usage is minimized.

NOTE : Each type of lug capping machine is chosen based on production needs, the scale of operation, and budget constraints.

Lug Capping Machines applications :

Lug capping machines are used in various industries to apply and secure lug caps (twist-off caps) onto jars and bottles. These machines ensure a tight seal to maintain product freshness, prevent leakage, and enhance shelf life.

- Food Industry : Used to seal jars of ketchup, mayonnaise, mustard, salsa, and other condiments.

- Beverages : Sealing bottles and jars containing fruit juices, syrups, and concentrates.

- Pharmaceuticals : Ensuring a hermetic seal on bottles to maintain sterility and prolong shelf life for herbal medicines and supplements stored in jars.

- Cosmetics and Personal Care : Capping jars of face creams, body lotions, and hair care products.

- Chemical Industry : For chemicals and cleaning solutions stored in jars.

- Agricultural Products : Sealing jars of canned vegetables, fruits, or other agricultural products.